In OLI, we know that every vibrating machine is unique.

For over 60 years, we have been using vibration to move, screen, separate and discharge materials.

This experience enables us to cater to the needs of each customer, from mining to milling, pharmaceuticals to foundries.

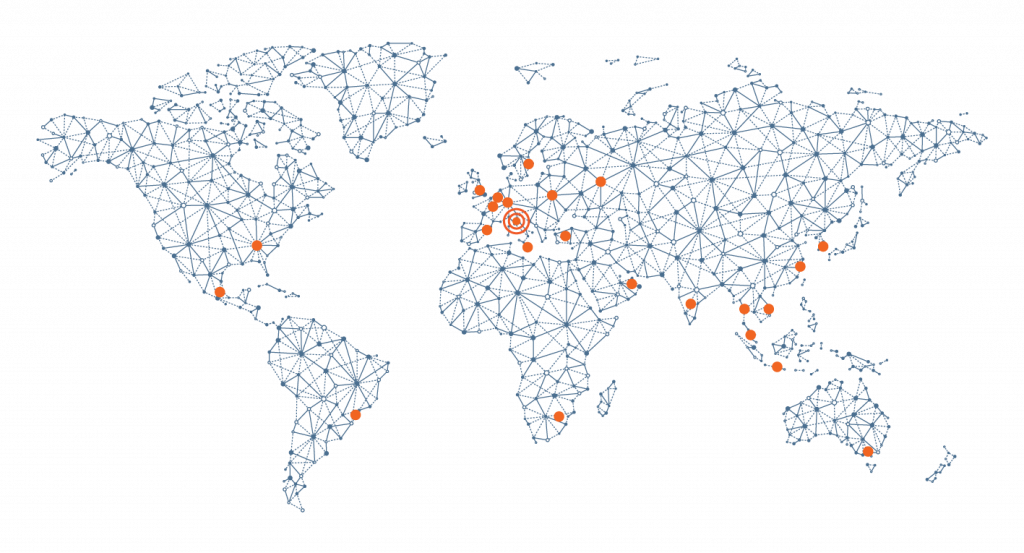

OLI: When you need it, where you need it.

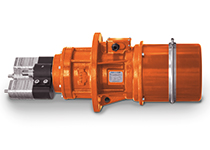

The OLI line of industrial vibrators is versatile and suitable for various sectors, including construction, mining, food, and recycling, and can be utilized worldwide. These electric vibrating motors can produce up to 40,000 kg of centrifugal force and are available in various voltages.

Download the catalogue

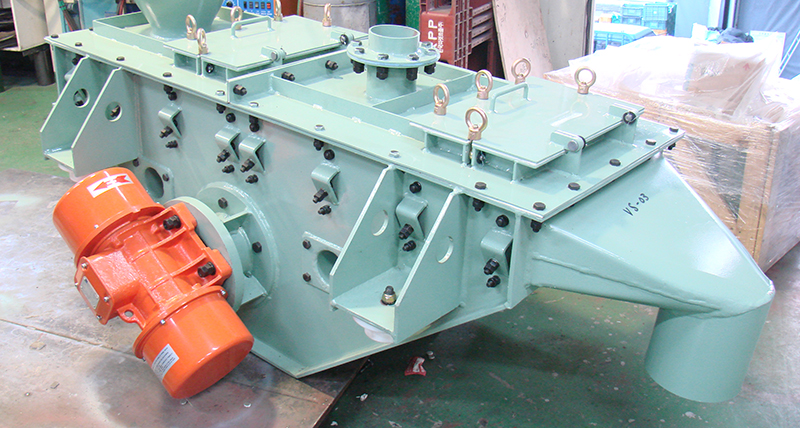

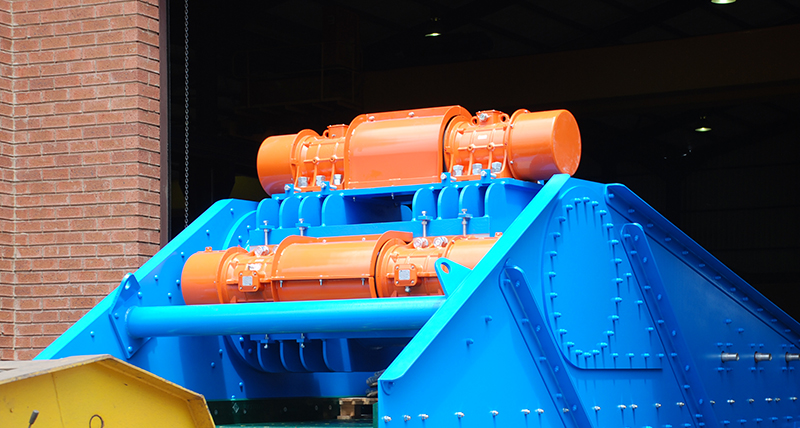

OLI’s vibrators can be used in a wide range of applications, including mining, construction and manufacturing. They are designed to meet the needs of both large and small contractors, providing high performance.

Using the most recent technology, components, and premium materials, OLI vibrators are created and put together. First-choice aluminum alloy, cast iron, and steel alloy are used in the assembly of the support flanges, motor bodies, and shafts, all of which were designed using FMEA criteria. As a result, the vibrator can be mounted on HEAVY-DUTY applications while still delivering EXCELLENT PERFORMANCE and safety in all circumstances.

Class F Insulating materials that have been vacuum-impregnated increase dependability and durability. Quality BEARINGS and a reliable grease sealing system provide long-lasting performance and minimal noise. Furthermore, the adjustable eccentric masses make it simple to calibrate the centrifugal force produced by the motor and adapt it to each application.